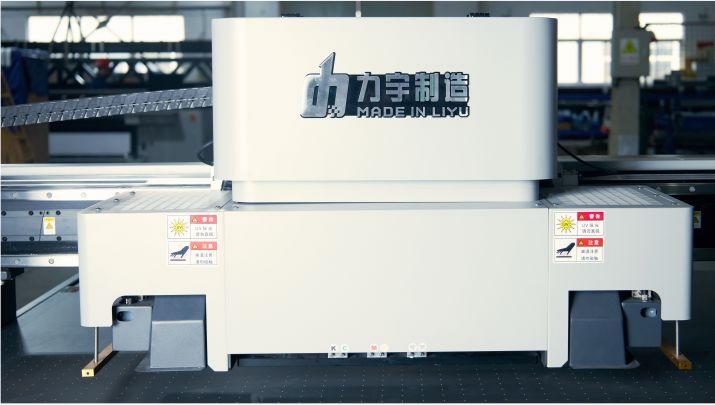

1. Mechanical Advantages

The machine frame is integrally welded and aged for durability.

The aluminum alloy honeycomb aluminum plate is provided with decimillimetre precision and high flatness.

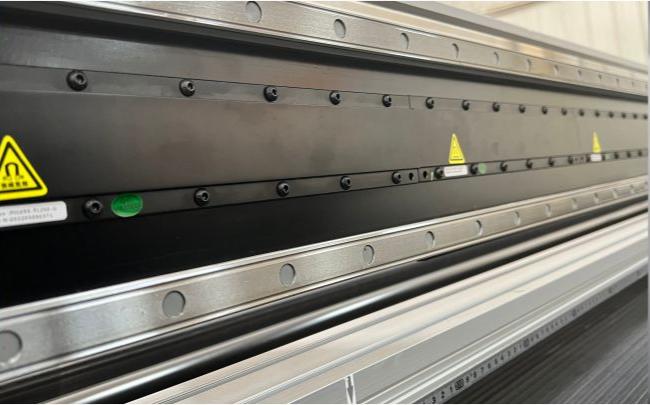

Dual mute guides in X direction allow for noiseless printing.

The Y direction is driven by classic dual guide guides, dual lead screws, and dual AC servo motors, providing high printing stability.

2. Attentive Design

High-quality static electricity eliminator improves printing quality.

Automatic media height measurement facilitates printing of various thickness materials.

The positioning pin function facilitates repeated printing of batch materials.

The equipped computer stand adsorption control system can print materials of various sizes.

The carriage anti-collision system can maximize the protection of valuable components like print heads and UV lamps.

3. Print Head Configuration

High precision and high cost-effective print heads with 5 pl / 15 pl variable droplet volume.

3200 nozzles; firing frequency: 4-level grayscale, with the max. of 24 KHZ.

Maximum printing width: 67.5 mm.

4. Curing Components The high-quality water-cooled LED system allows materials not to deform with low power consumption for eco-friendly operation.