1. One Belt, All Substrates Covered

It can handle a series of flexible and rigid materials such as flexible film, coated banner, car sticker, high permeability film, reflective film, 3P fabric, KT board, cardboard, and polyvinyl alcohol. Besides, it has the remarkable characteristics of zero waste of printing media, no error in long-size printing, and no cutting in full-roll production.

2. Precision Printing

Start printing immediately – no compensation media or guiding cloth required. Finished prints are ready for direct installation, saving costs equivalent to multiple rolls annually.

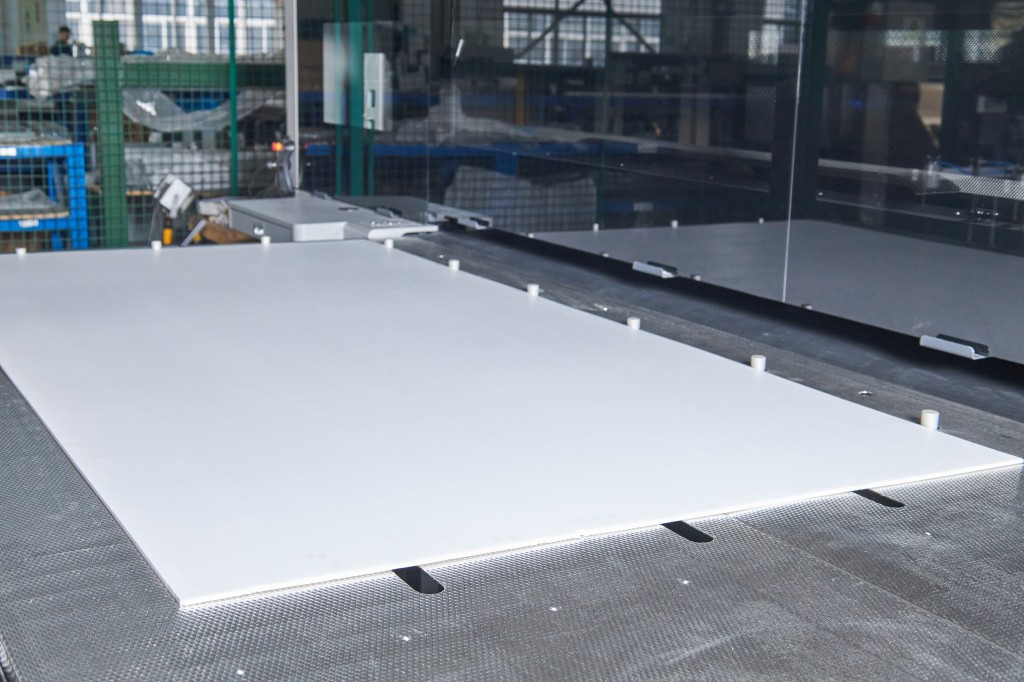

3. Four-Zone Variable Vacuum Adsorption

Soft materials are wrinkle-free, and hard materials are warp-free when printing. Automatic airflow adjustment ensures flawless application even for beginners.

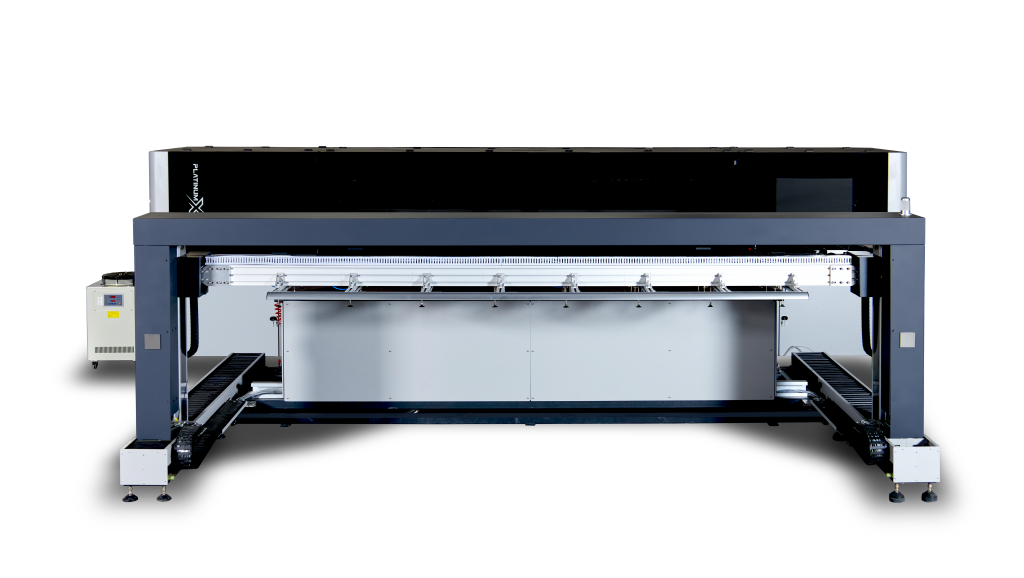

4. Full-auto guide belt guiding system

No deviation or deformation throughout long-format printing – The 10-meter graphics align with millimeter precision from end to end.

5. User-Focused Details

• Original dual-handle design: Flexible control for quick and easy operation

• Dual screen (front/rear): Single-operator can control from both ends

• Triple roll take-up and feeding system: 3.2m main roll + two 1.6m auxiliary rolls for simultaneous feeding

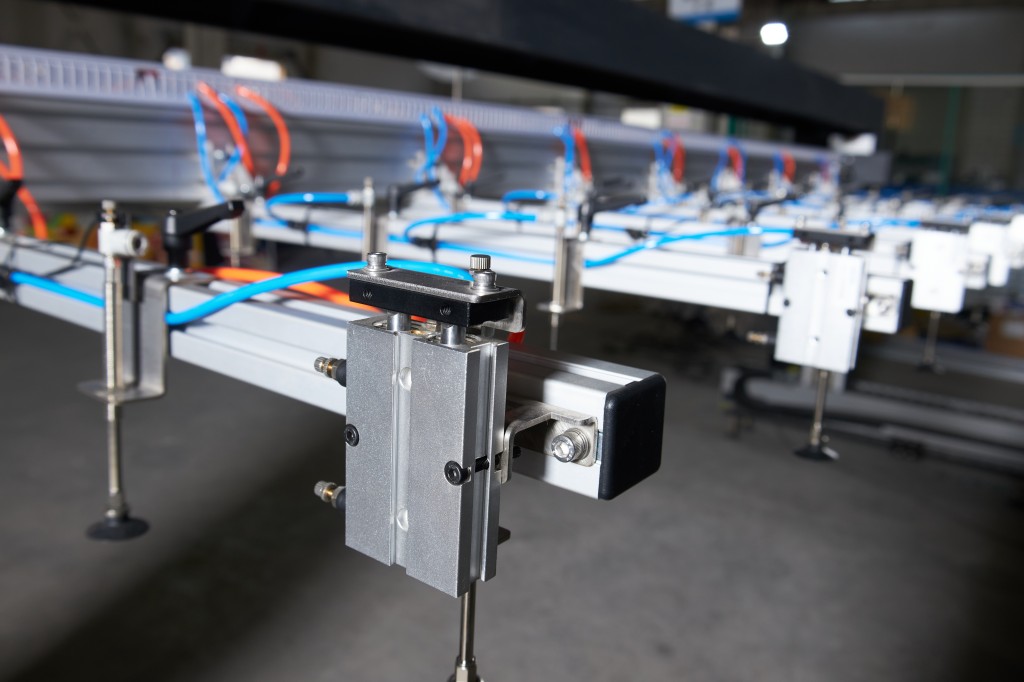

6. Hands-Free Print Head Maintenance

Optional automatic ink scraping and automatic cleaning functions keep print heads in prime condition with zero-contact maintenance.

7. Independent Front/Rear Take-Up and Feeding System

Three-roll continuous operation enables non-stop order switching – ensuring high efficiency even for small batches.

8. Instant Sheet Positioning

One-touch front-rear buttons + board card positioning enable continuous batch printing without material shifting.

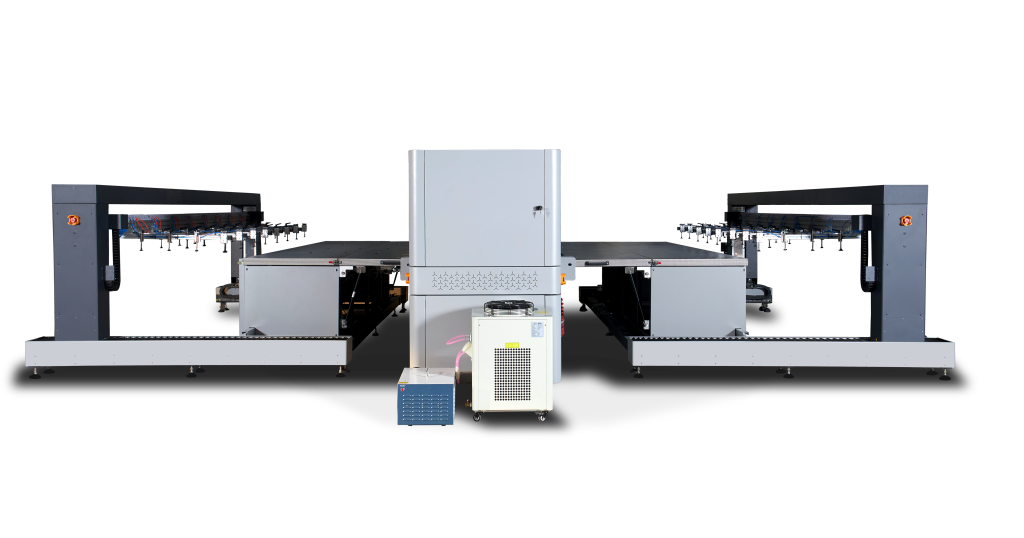

9. Complete Unmanned Solution

Fully automated loading/unloading system integrates unwinding, printing, and feeding, achieving true "lights-out factory" operation.