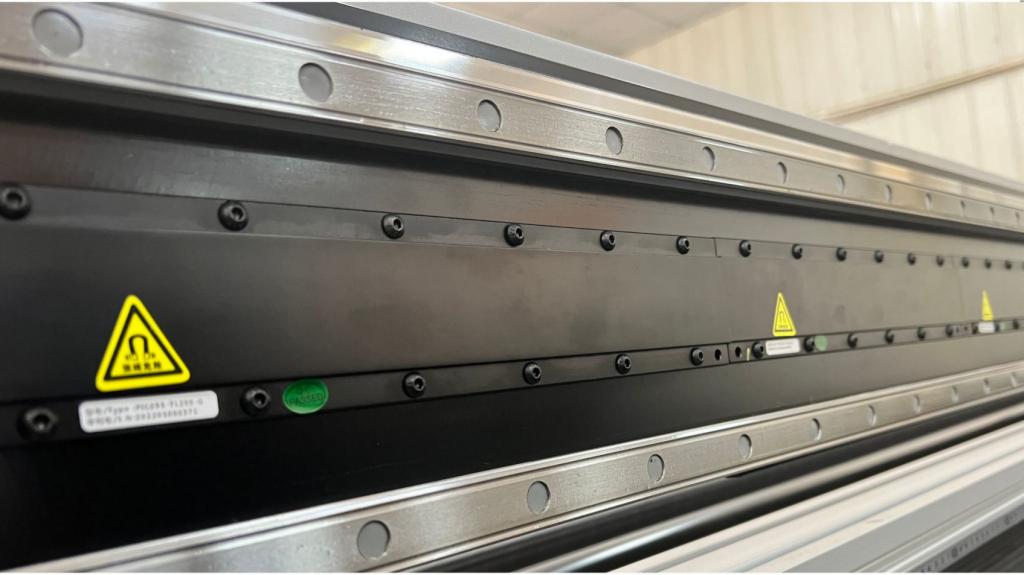

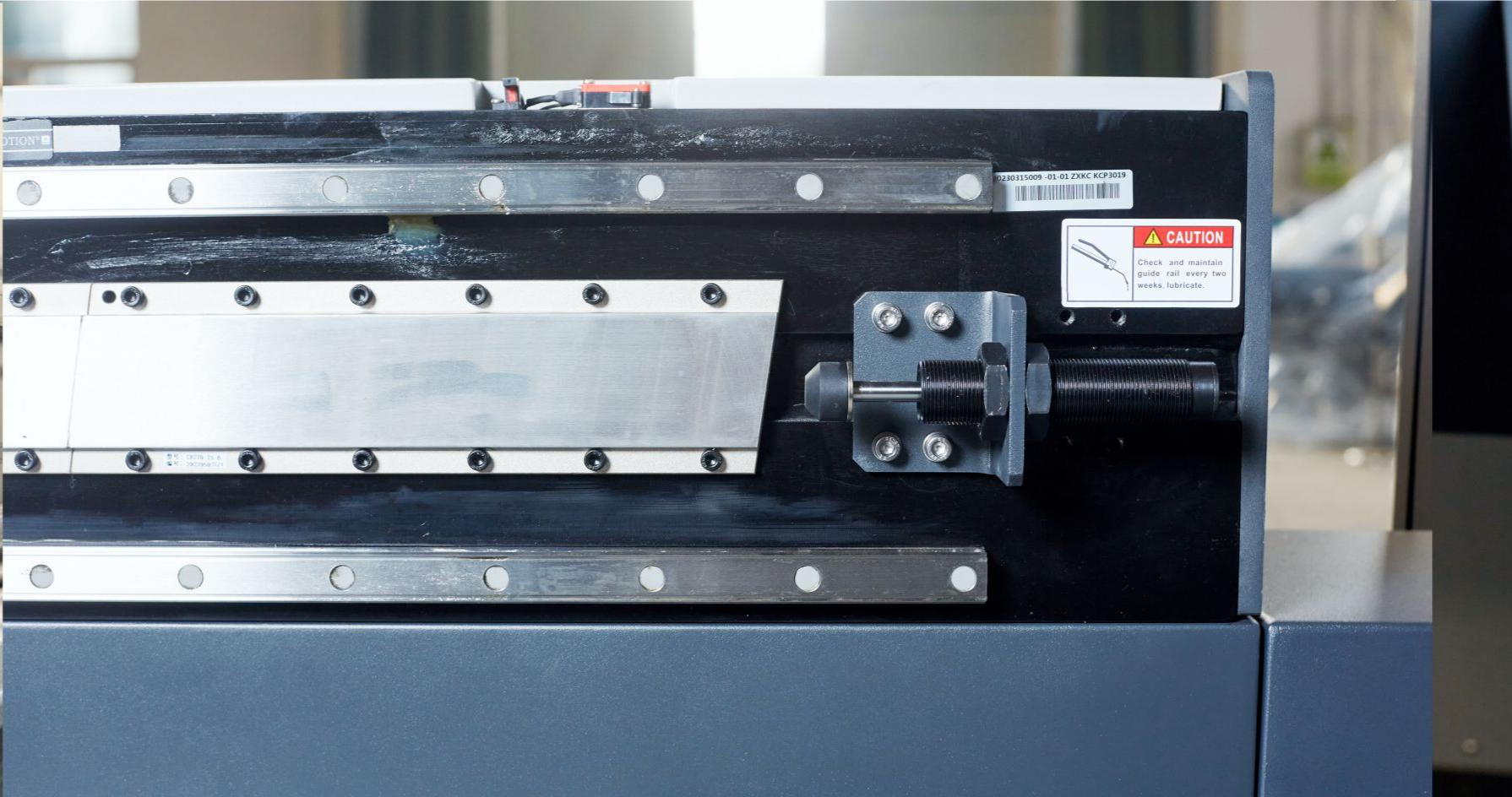

1. The printer incorporates a metal grating and a triple linear motor system on the X/Y axes, ensuring quieter, more precise, and stable operation;

2. The unique dual-workstation with dual-handle control allows for alternate processing across two workstations, significantly improving work efficiency;

3. The combination of front and rear pneumatic positioning pins guarantees precise positioning during operation, enabling users to complete various printing tasks with greater ease;

4. The independent air flotation function assists operators in effortlessly loading and unloading large-format materials;

5. The intelligent ink supply system provides a more stable ink supply for the equipment, meeting the stable demand for ultra-high-precision UV printing;

6. Equipped with newly upgraded LED curing technology, a single equipment can realize seamless switching between multiple printing modes so as to accommodate various application scenarios;

7. The newly upgraded safety light curtain and optimized anti-collision continuous printing function ensure safety during operation, allowing users to work with greater peace of mind.